The Challenges

Solve your biggest challenges with a single solution

Click to learn how our factory-wide ecosystem solves each challenge.

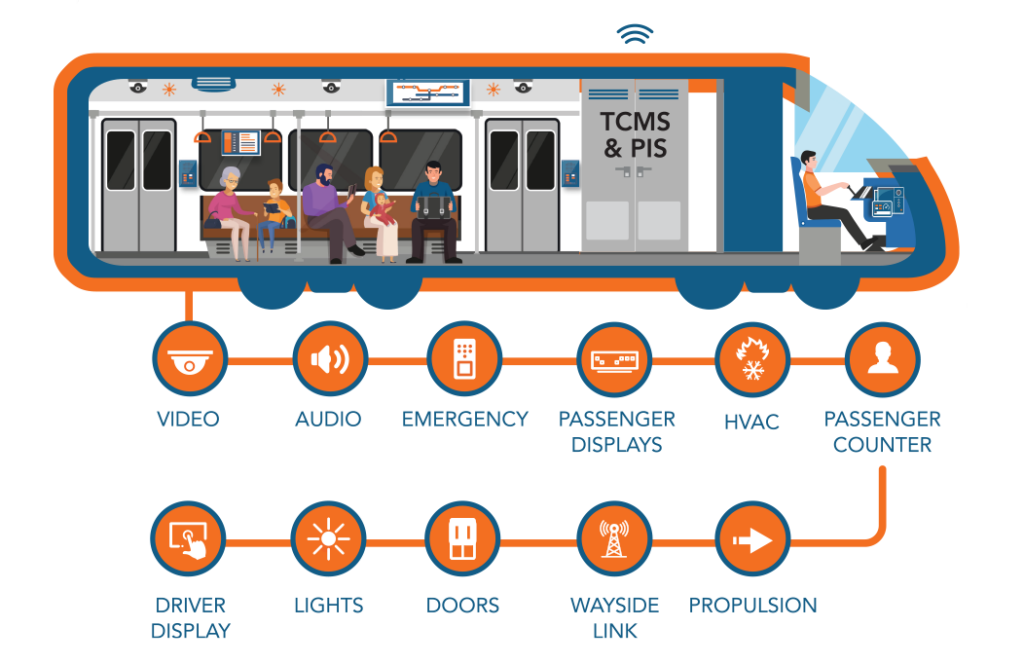

Modular, integrated TCMS and PIS

Trainwise is the world’s most advanced TCMS and PIS solution. A unique, modular, integrated design makes it fully customized to comply with all project specifications, industry regulations, and customer requirements. It features the newest network standards, cybersecurity, interface design, and fleet-wide video, with advanced tools that help simplify integration. Designed to maximize efficiency, reliability, and passenger satisfaction, Trainwise is also enabled for wayside management with our Fleetwise EFMS, helping your clients maximize fleet readiness and state-of-good-repair while cutting operating and maintenance costs. And everything is covered by our Total TrainLife Care™ long-term support.

Automated Testing

Use advanced system integration tools for testing connections and communications. Replace manual tasks with automated scheduling for subsystem software configuration, serialization, and network tests. Schedule tasks for any time of day or night. Save time with preconfigured, automated off-car factory self-tests.

Automated Software Tasks

Take advantage of automated TCMS subsystem software and PIS content uploads and version validation.

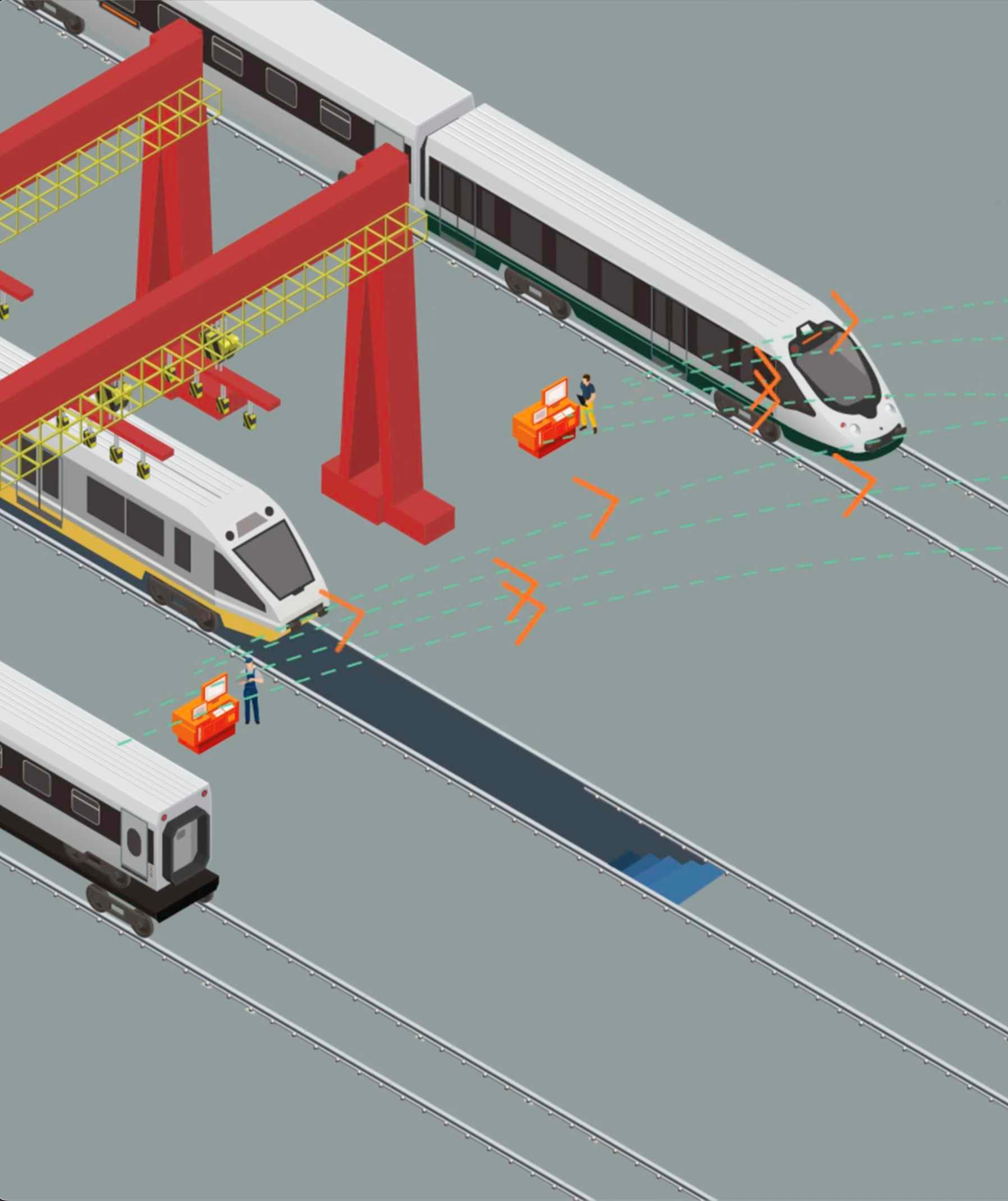

Factory-Wide Connectivity

Get real-time visibility of the build and test status for every car, at every stage of production. Automated reporting delivers a complete train build history with proof of correct operation and configuration, which also helps shorten the customer acceptance process.

Powerful Diagnostics & Data Sharing

Simple-to-use diagnostics tools validate performance and help troubleshoot defects quickly. Share fault information to enable collaboration. Data and diagnostic tools are shared across engineering, production and sub-supplier teams to enable collaboration on problem-solving. Server-stored data enables off-line troubleshooting, even when cars are unpowered.

Fleet-Wide Connectivity

Data sharing enables simpler customer collaboration, with access to daily maintenance status and the complete histories of each train. When an issue arises, use the same tools as the factory for rapid troubleshooting.

Partner With A Leader

Quester Tangent is ranked in the top 5% of passenger rail suppliers in quality system scores. Our state-of-the-art facilities and coordinated processes allow our teams to deliver efficient, turnkey solutions that integrate in-depth engineering expertise, extensive manufacturing capacity, project management, customization, system and network integration, and long-term support. And if a difficult problem comes up, you get fast access to our factory or field experts.

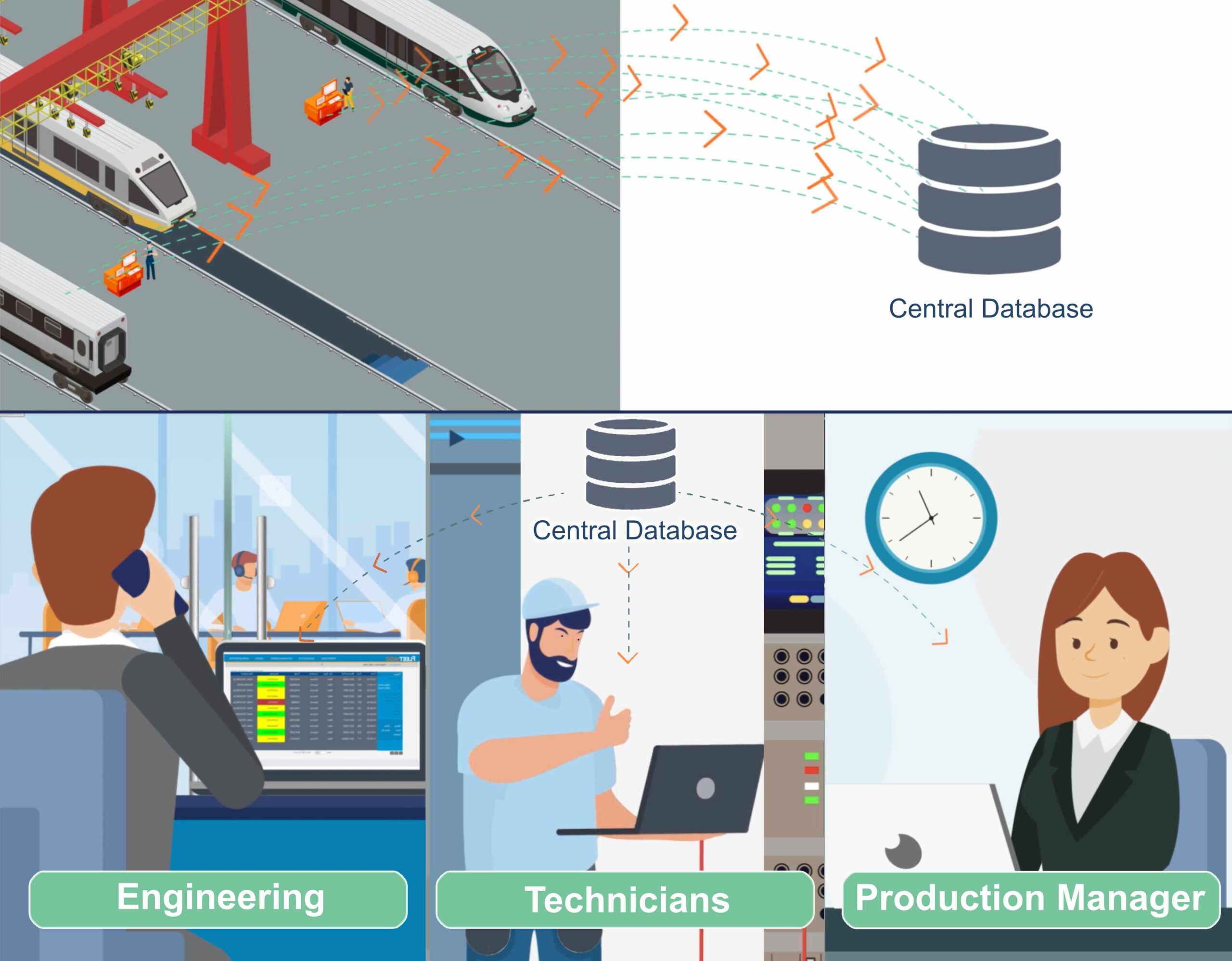

A train-wide, factory-wide ecosystem

Smarter electronics, smarter tools, smarter workflows

Our highly integrated and customized TrainWise TCMS and PIS include the newest technologies, helping your clients keep trains running and passengers happy.

Every sub-system on every train connects wirelessly, securely, and continuously with our wayside Fleetwise train factory management system. You’ll boost efficiency during integration, testing, troubleshooting, and validation by using automated analytic tools and data sharing between engineers, technicians, the production manager, the warranty team, and your customers.

Whether connecting across the factory floor or to an in-service fleet, Trainwise and Fleetwise will help you:

Fleetwise TFMS

Factory-wide connectivity with time-saving integration, production and warranty tools

Traditional train production methods require time-consuming manual on-car testing with minimal cross-team collaboration. The Fleetwise train factory management system (TFMS) offers connectivity with onboard TCMS and PIS across all cars on the factory floor. You’ll get data sharing across teams, automated testing and configuration tools, and fast access to technical support. This helps your teams optimize workflows by saving time during prototype and production stages, solving problems together, and improving consistency and accuracy across all car build phases, even for complex systems. Warranty teams will also save time and cost by remotely connecting to in-service trains, using powerful diagnostic tools to isolate issues, and simplifying customer collaboration.

Trainwise TCMS & PIS

Delivering the onboard technology that transit authorities demand to keep trains running and passengers happy

Trainwise includes our train control and monitoring system (TCMS), smoothly integrated with our passenger information system (PIS). As a market leader, we go beyond traditional approaches by offering modern Ethernet communications across both TCMS and PIS.